Not everyone can immediately see the similarities between the aerospace and marine industries, but there are more than one might think.

“In the marine industry, we benefit not only from unique and original ideas but also the expectation of producing composites at a very rapid pace,” says Oliver Moore, co-owner and co-founder of Moore Brothers Company. From experience, the Moore Brothers team appreciates their agility is an asset when pitching to prototyping in other industries such as aerospace.

Specifically, what Oliver is referring to is the marine industry’s ability to build the lightest, fastest boat possible that won’t break under extreme pressure. Sailing teams that race in the America’s Cup have three years to create that boat: from starting with an idea to having a vessel that can reach speeds well over 40 knots. “The aerospace industry looks at that and thinks it’s impossible.” Says Oliver. “Each competition has a new design rule and teams have 3 years to design, build and learn to sail their best effort to challenge for the Cup on a set date.”

By using a tried and true model, the team at Moore Brothers is well equipped to produce a range of one-off composites within specific tolerances - and fast. “We’re never building the same thing twice.” Says Oliver, “which means our team has to be agile, creative and of course, highly-skilled.”

For the most part, America’s Cup boats and rockets are made out of the same materials these days, but, according to Oliver, many of the aerospace factories just aren’t built to produce prototypes on the schedule that some companies want them.

Due to the countless certifications that a company needs in order to manufacture aerospace parts, most companies take on bigger and multiple contracts in order to cover the costs of certification, production and workforce. That means long wait times for companies that are trying to get funding for their ideas. For prototyping, that just doesn’t work. Companies want their prototypes ASAP.

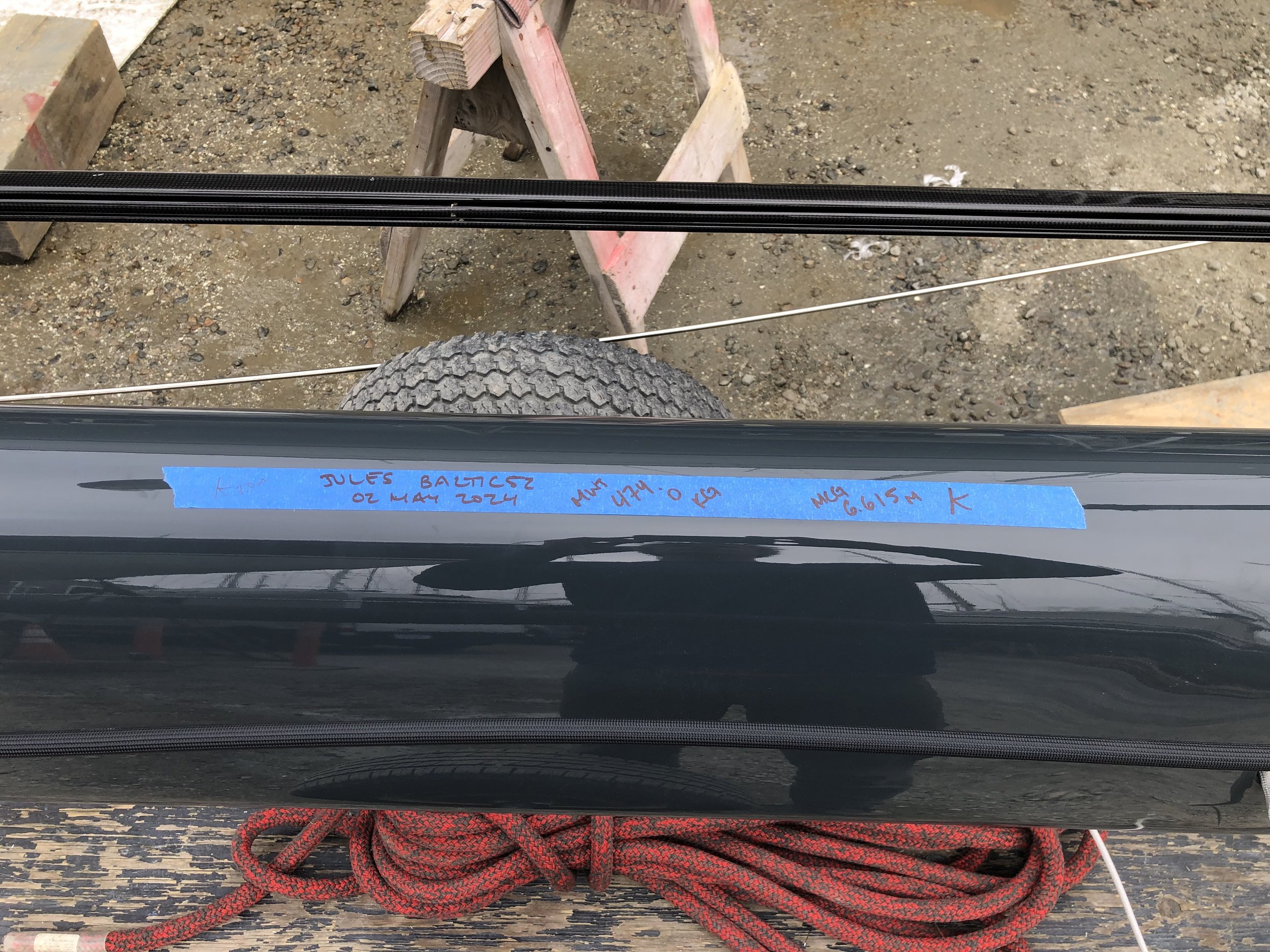

“In the marine world we are processing fully custom composite system jobs from design through install on the order of 6 to 12 weeks. Be they masts, rudders or ballast systems. You need to have very strong but flexible systems in place to be able to do that at a high level. The marine industry gives us the opportunity to build and hone those systems which are directly transferable to the industrial/aerospace world.”

The U.S. aerospace industry is the largest in the world and is expected to have a Compound Annual Growth (CAGR) of 2.4% between 2023 and 2028.

The green race in aerospace

Many people might think of your traditional airplanes and rockets when the word “aerospace” is brought up, but with the push to reduce carbon emissions to combat climate change, the amount of companies focusing on building electric planes and helicopters is also growing. These companies need innovative composite companies to help them build prototypes. “We were already very creative in how we approach problems,” says Oliver, which is why it felt like a natural fit to start working with aerospace companies.

Recently, Moore Brothers Company helped design and build a quarter-scale model of the wing-in-ground effect vehicle for REGENT that flew over Narragansett Bay last year. Although REGENT’s electric seaglider is not considered to technically be an aircraft (it is a maritime vessel), it will fly just above the water utilizing the reaction of air against the surface of the water. That being said, it does fly and REGENT has signed aviation contracts worth billions of dollars with companies around the world.

In April, Moore Brothers Company built a full-scale mock up of what will ultimately be a passenger carrying glider. The following month, REGENT announced that Moore Brother Company will be the main partner in creating the necessary components for the 65-foot carbon composite wing and hull for the company’s full-scale seaglider prototype. Oliver said that they most likely got the contract because they could produce what REGENT wanted at a reasonable price and on the company’s timeline (they want to have passenger-carrying vessels in operation by 2025).

Moore Brothers Company currently employees over 40 design engineers, composite and machine techs and management staff. Beyond that, there is plenty of talent to pull in for larger projects. When it came to the REGENT Project, Moore Brothers was contracted to produce the majority of the components for the company’s first full-scale prototype. Oliver brought in additional talent and manpower by contracting Zack Parent and the team at Ocean State Composites to manage fabrication of the vessel’s hull - a 55ft fuselage - by working onsite with the Moore Brothers Team. “We are excited to be part of these projects with Moore Brothers Company,” said Zack, noting that crucially, “we all work well together as a team.” Their experience in fabrication within leading America’s Cup syndicates and other racing programs made Zac and Ocean State Composites a crucial part of delivering high-quality components on time and at the required scale.

“We work with our community in a collaborative way” says Oliver, which, he says is more similar to how larger contracts are fulfilled in Europe: utilizing sub-contractors when needed.

Not forgetting their maritime roots

Although the Moore brothers plan on continuing to expand their business in the aerospace sector, they are not forgetting their roots. “Maintaining our marine industry business and progressing alongside valued clients will only strengthen our ability to service those in other industries.” Says Oliver.